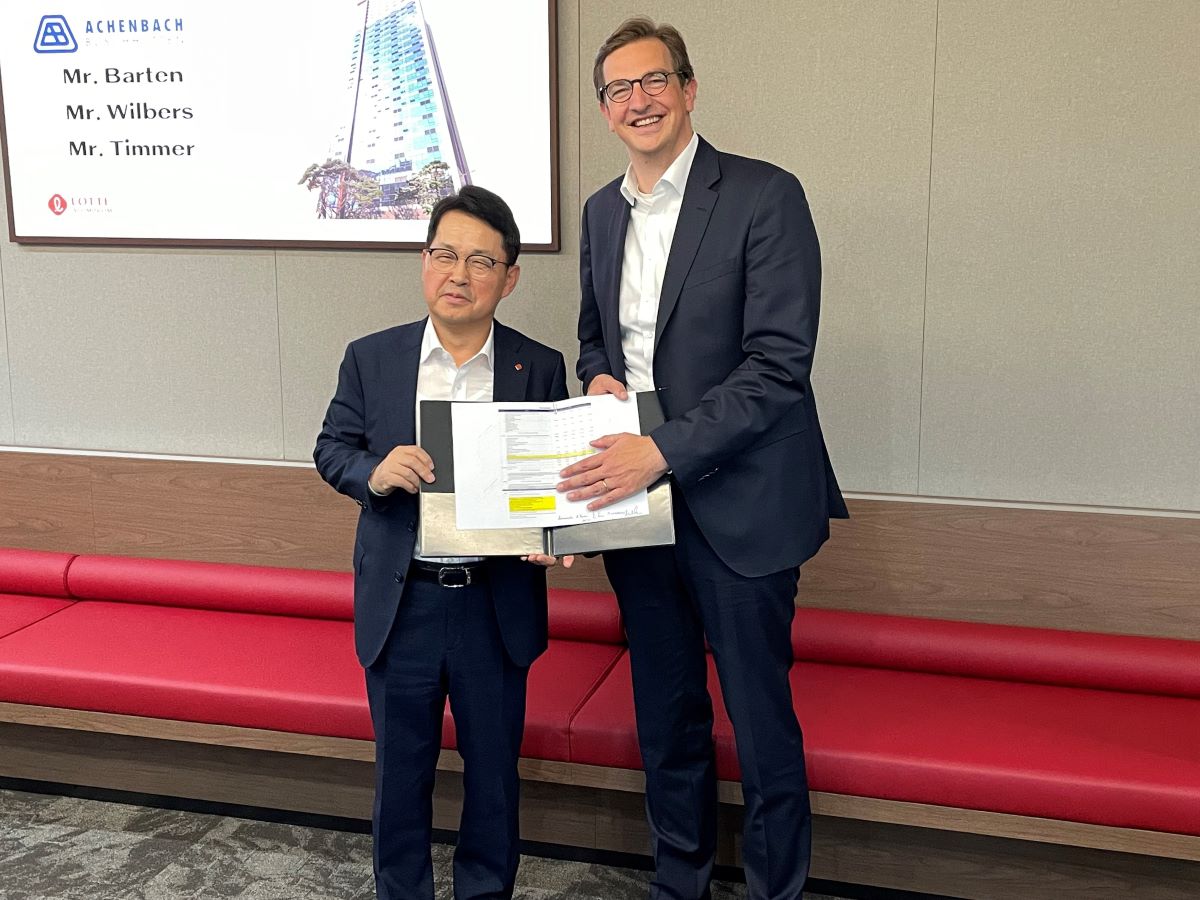

Achenbach has been awarded to deliver high-tech mill and slitting equipment for the first greenfield battery foil plant on the American continent. Achenbach's long-standing customer Lotte Aluminium Co., Ltd. has agreed to set up a joint venture with LOTTE chemical to build the production facility for battery cathode foil in Kentucky, USA, which will have an annual production capacity of 36,000t of foil to equip about 4,000,000 electric cars. "We are pleased that we can now supply our pioneering technology to the US after many years of deindustrialization in this market”, says Achenbach President & CEO André E. Barten. Achenbach, being active in the field of battery technology for several years, is a specialist when it comes to rolling, slitting, and processing the sophisticated cathode foil at high speeds. But the fact that Lotte decided in favor of Achenbach for this major investment is not only due to its expertise, but also to the trusting business relationship between the two companies.

"Based on the successful cooperation, the project teams of both companies are closely connected. We have already mastered the mammoth task of ramping up such a large high-tech plant together once - the project in the USA is now another significant milestone”, explains Thomas Timmer, Sales Director at Achenbach and mainly responsible for the project. The new order is not only groundbreaking in terms of technology, but also in terms of sustainability. The machines are characterized by innovative technology components and a high degree of automation, which have the lowest energy consumption as well as extremely low emission values due to special exhaust air purification systems.