Technology for Future Concepts

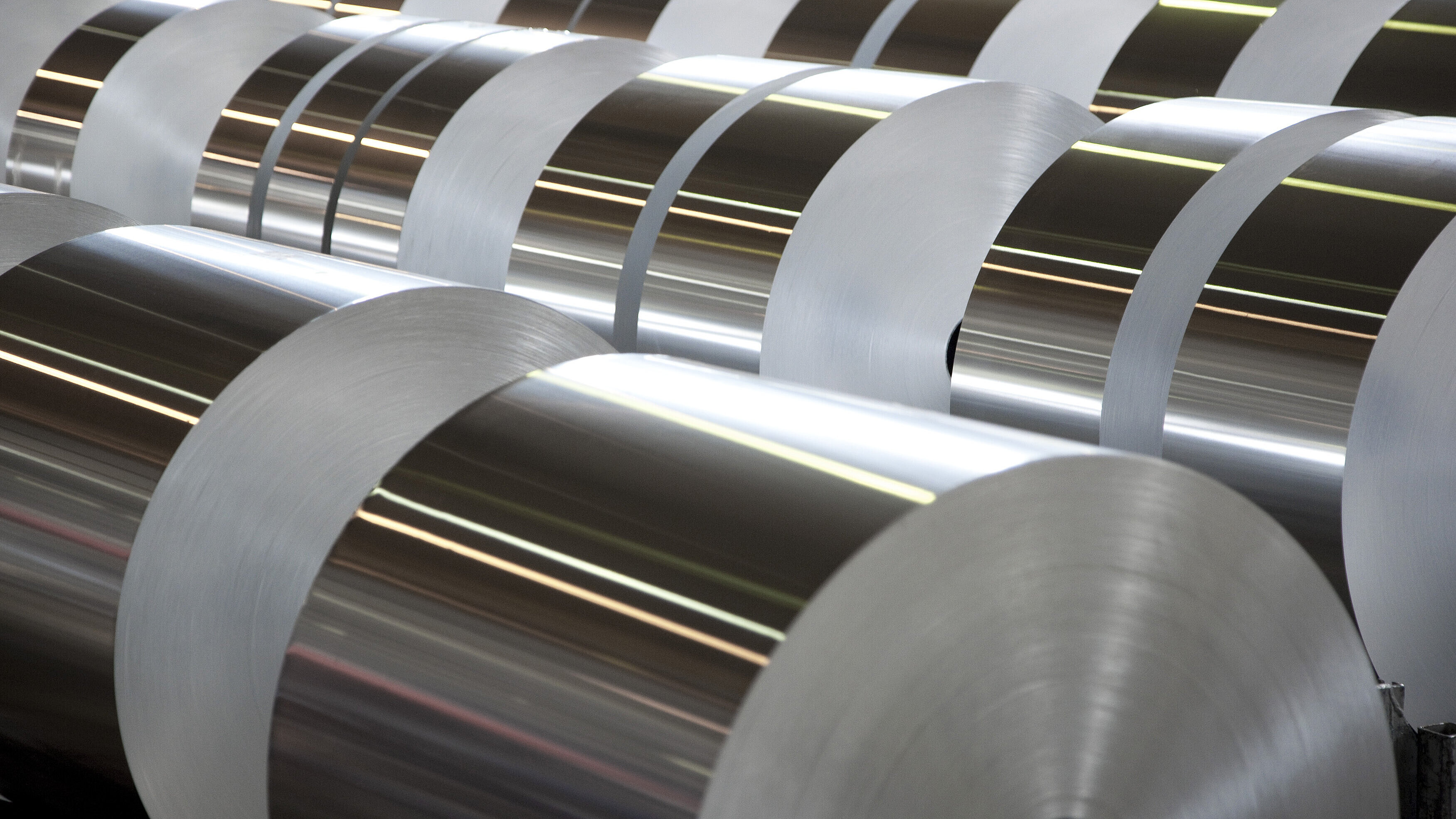

Achenbach is the specialist for rolling and foil slitting technology to produce aluminium flat rolled products at the highest quality level. With our knowledge, we help our customers to realize their future ideas, develop new products, and to be successful in their markets.

What makes the difference

“To make changes for the better. To be one step ahead.

For products that serve a wider purpose and machines that can make this possible.

Machines that last generations and are built for a green, lean, and digital future.”

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.