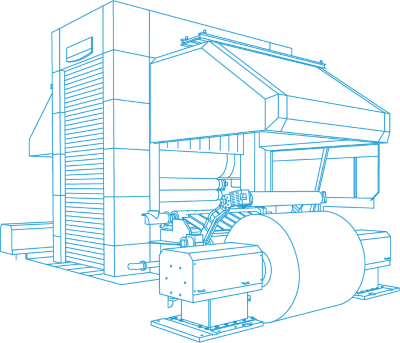

Achenbach UniSpray®

Coolant distribution system

Achenbach

UniSpray® Coolant Distribution System

Key element to influence local flatness deficiences enhancing the productivity and quality of the rolled products.

A holistic approach.

The Achenbach UniSpray® Coolant Distribution System is the key element to influence local flatness deficiencies.

In this context the perfect interaction between the Achenbach UniSpray® Coolant Distribution System and the flatness measuring with Achenbach UniFlat® Flatness Measuring Roll results in the superiority of the Achenbach OPTIROLL® i3 MillFlat Strip Flatness Control System which is characterized by highly dynamic control loops.

Aiming at enhancing the productivity as well as the quality of the rolled products, the Achenbach UniSpray® Coolant Distribution System is used in both, new and modernized rolling mills for non-ferrous metals. Two designs are available:

- Proven coolant distribution system; individual valves wired up to the control cabinet

- New coolant distribution system: Integrated AS-i bus system for controlling the individual valves in each nozzle valve header

- Integration of hot edge sprayers for flatness control at the strip edges possible

At a glance

For rolling non-ferrous metals, rolling oil is an indispensable coolant and lubricant. The Achenbach UniSpray® coolant distribution system guarantees the application of rolling oil onto the work roll barrel ultra-precisely in time and spot. Therefore, this system is an essential actuator of most modern flatness control with Achenbach OPTIROLL® i3 MillFlat.

Especially in foil and thin-strip rolling mills, the thermal barrel may severely decrease beyond the strip edges due to a lack of forming energy. The consequently occurring flatness deficiencies cannot be eliminated by cooling the rolls.

- Micro-dosing of the oil quantity by multi-row arrangemant of the nozzle valves

- Compact and robust design of the nozzle valve headers

- Easy to retrofit, in twofold extent, as single technology component and as actuator of the Achenbach OPTIROLL® i3 MillFlat flatness control system

- Bus system integrated into the nozzle valve header with the additional benefit of high maintenance friendliness

- Easy maintenance of the valves without disassembling the entire header

- Use of Achenbach Hot Sprayers System at the strip edges as an option

- Design in stainless steel as an option

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.