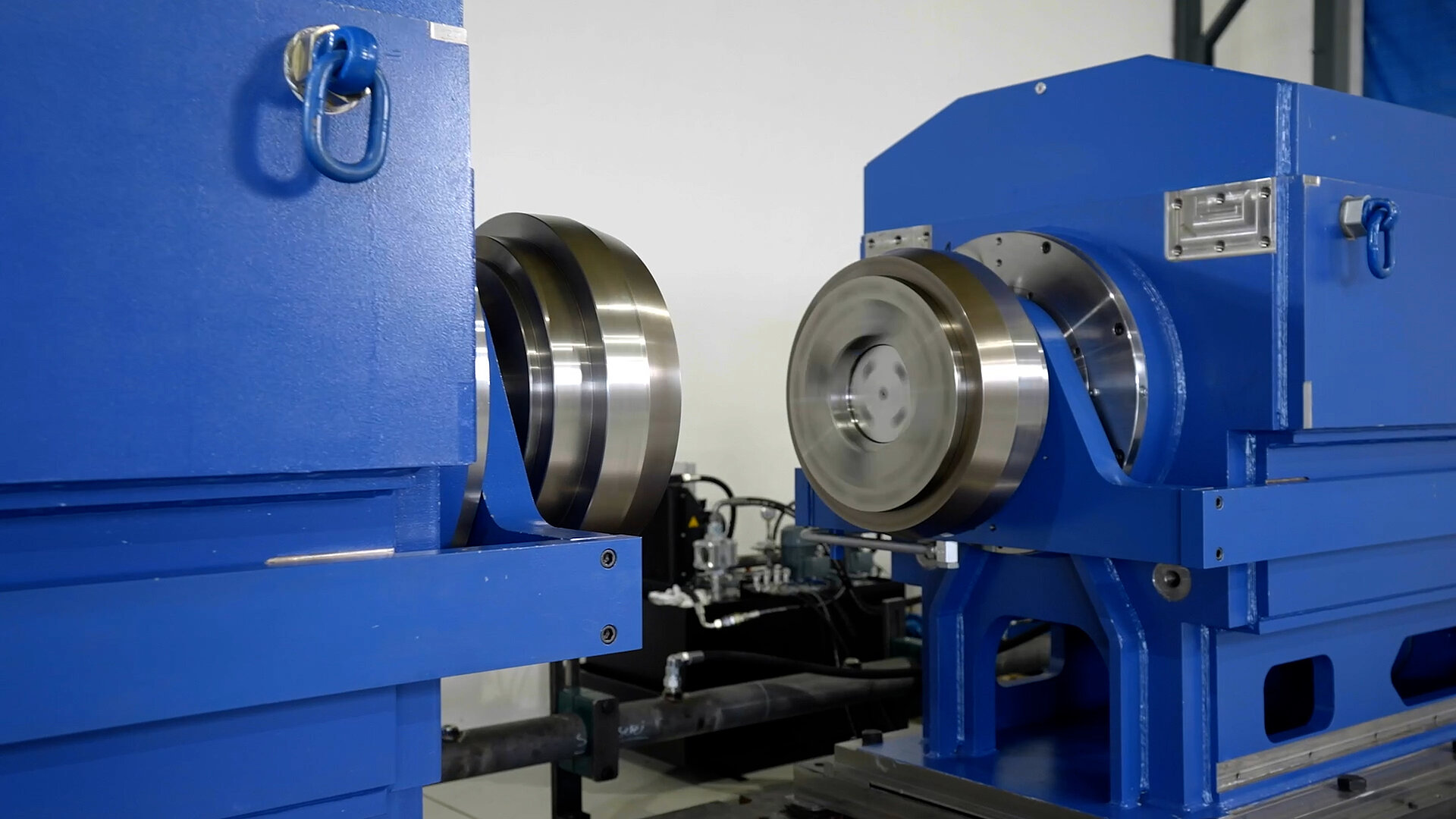

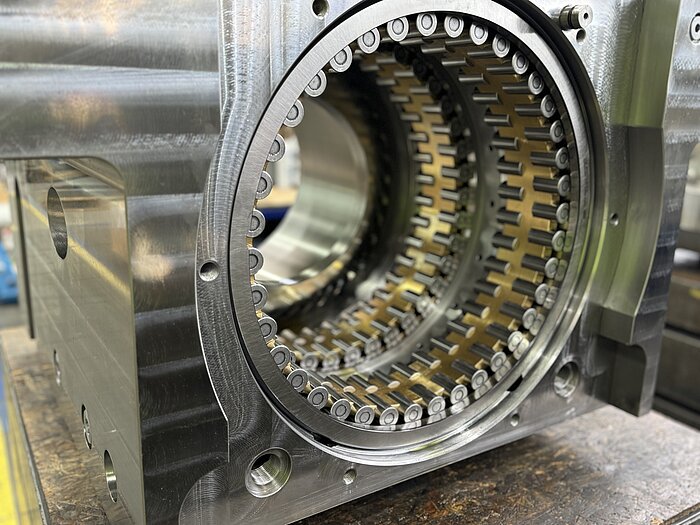

One of the main goals at Achenbach is to further optimize our machines and technologies to meet the requirements of our customers. One component that is now increasingly finding its way into our customers' orders is the Achenbach UniTorque® Direct Drive Technology. This technology, which replaces the classic single or tandem motor configuration, has several comparative advantages. The motor is directly integrated into the coiler, which reduces the costs for manufacturing and fabrication. Also, costly foundations are no longer required and significant space savings are achieved.

Furthermore, the UniTorque offers high torques and high drive stiffness combined with a compact design. This makes an increased efficiency and a reduction of the energy demand possible. The efficiency is about 4% higher than the efficiency of the "classic solution with a single motor". Compared to a classic tandem motor configuration, the efficiency is even about 10% higher. Likewise, the new drive can achieve energy costs of 8-10% compared to the classic solutions.

With this technology, we have developed another sustainable solution for our customers to minimize the CO2 footprint of the production - according to our guideline Green.Lean.Digital.