Achenbach OPTIFOIL

SepaSlit®

ACHENBACH OPTIFOIL®

SepaSlit

Separators serve for separating and slitting the doubled foils after the last rolling pass in the production of thinnest aluminium foils.

Slitting section with highly-precisely adjustable four-axis razor blade holders

Inline detection system from even finest holes (PHD) in combination with a comprehensive quality reporting to the final customer

Hydropneumatic, weight-balanced pressure system with innovation double diaphragm cylinder

Achenbach OPTIFOIL SepaSlit®

Rewinding diameters

Speeds

Coil weights

Foil thicknesses

A holistic approach.

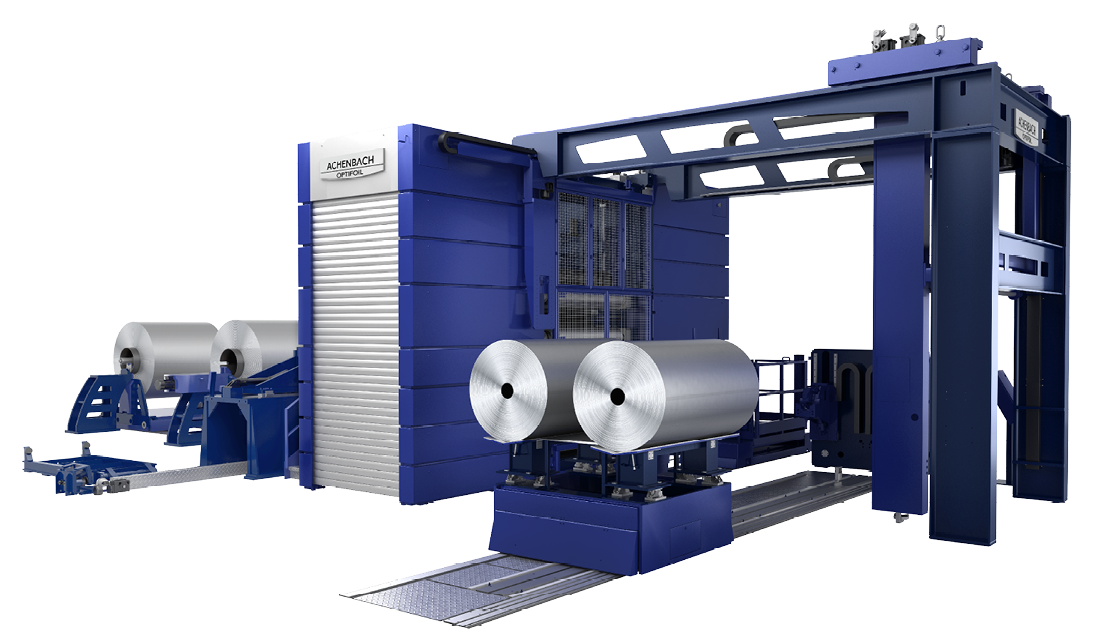

Designed to finish roll diameters of up to 600 mm, up to 850 mm, up to 1,016 mm or up to 1,200 mm they are always tailored to the specific operation purpose.

For each new separator or those to be modernized, a holistic approach to perfectly synchronize mechanics, hydraulics, automation, and drive technology in their complex interaction is applied.

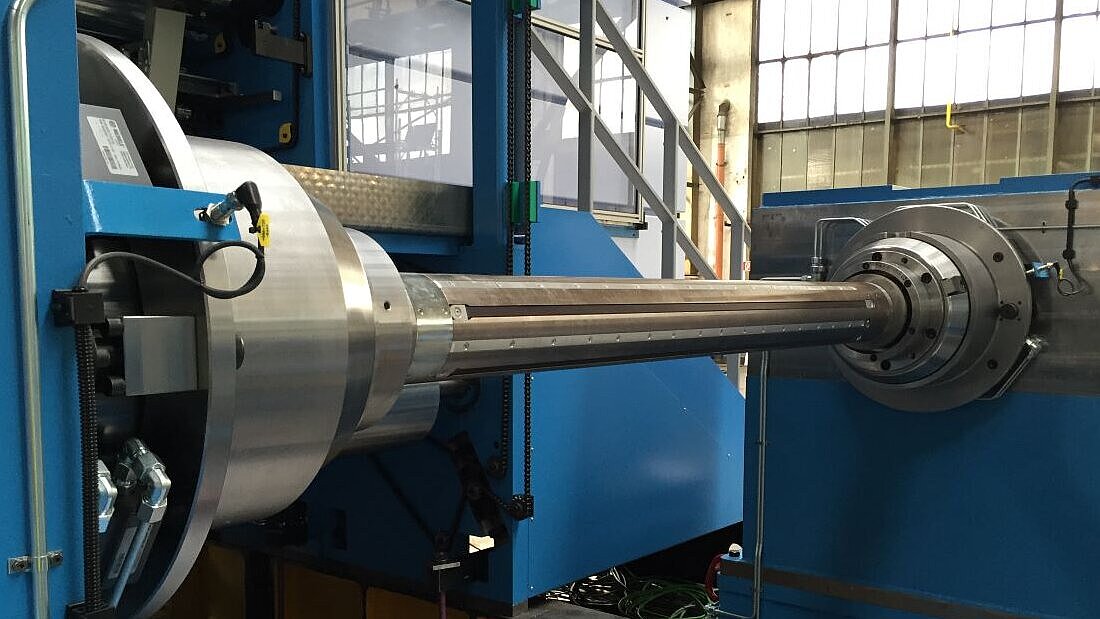

The OPTIFOIL Separator consists essentially of a coil deposit, a cart, an unwinding unit, a material threading device, a center unit with slitting device (razor-blade and/or shear-cut), a separation device and welding device, two winders and a finished roll handling unit. Each Separator features a very short material transport path.

A variety of useful automation and process engineering options allows the system to be easily adapted to individual customer requirements. Examples of this include various empty spool or finished roll handling systems that allow, for example, a connection to an unguided coil transport system. All separators can be equipped with a pinhole detector.

- Slitting section with highly-precisely adjustable four-axis razor blade holders

- Hydropneumatic, weight-balanced pressure system with innovation double diaphragm cylinder

- Inline detection system from even finest holes (PHD) in combination with a comprehensive quality reporting to the final customer

- Maintenance-friendly machine enclosure

- Doctoring by winding shaft reception at the unwinder

- Functional, light-weight housing with integrated fully automatic material handling

The Achenbach SepaSlit®separate and slit the doubled aluminium foil for any downstream processing such as coating, laminating, printing for end products such as:

- Capacitor foil

- Pharma foil

- Converter foil

- Battery foil

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.