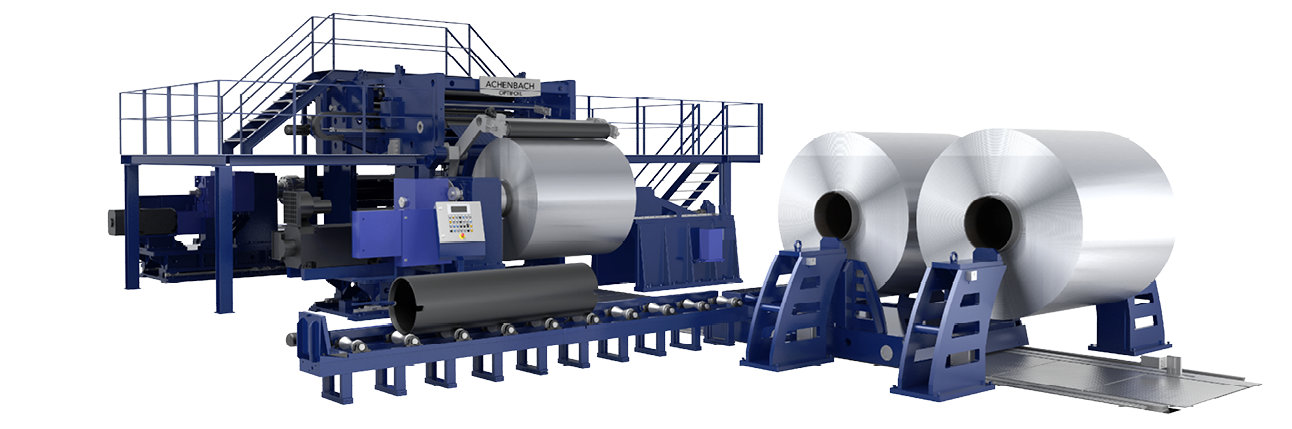

Achenbach OPTIFOIL®

Rewinder

ACHENBACH OPTIFOIL®

Rewinder

Rewinder service for optimum and effective rewinding and trimming aluminum coils onto other spools.

Automatic threading

Trimming with automatic width and depth adjustment

Strip edge control

Automatic spool feeding and supply

Ironing roller and belt wrapper at the recoiler

Achenbach OPTIFOIL® Rewinder

Speed Foil Rewinder

Rewinding diameter

Speed Strip Rewinder

Coil weight

A holistic approach.

The aim is to either produce the material ready for sale or to prepare the coils for the downstream rolling process and thus to optimize it. Depending on the strip thickness and the production target, two design types are differentiated: the foil rewinder and the strip rewinder.

Designed for rewinding diameters up to 2,100 mm at slitting speeds up to 600 m/min (foil rewinder) and 400 m/min (strip rewinder) as well as for coil weights up to 30,000 kg they are always tailored to the specific operation purpose. For each separator a holistic approach to perfectly synchronize mechanics, hydraulics, automation, and drive technology in their complex interaction is applied.

When the coil has been fed to the rewinder via the automatic feeding device, the strip is guided over various rollers up to the recoiler, where the material is wound with the help of a belt wrapper thus ensuring the required strip run stabilisation. Depending on the respective design, an automatic threading device or feeding tables in combination with transfer tables are used to guarantee fast threading of the coils.

An automatic cross cutting unit serves for cutting and disposing the inadequate strip nose to perfectly prepare the rewinding process. An ironing roller on the recoiler guarantees a high winding quality. The rewound strip is now ideally prepared for the subsequent rolling and further processing.

- Automatic threading

- Strip edge control

- Trimming with automatic width and depth adjustment

- Scrap handling

- Automatic spool feeding and supply

- Automatic feeding and removal handling

- Ironing roller and belt wrapper at the recoiler

- Working platform for optimum operating and maintenance of the machine

- Automatic cross cutting unit

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.