Achenbach OPTIFOIL

LightSlit®

ACHENBACH OPTIFOIL®

LightSlit

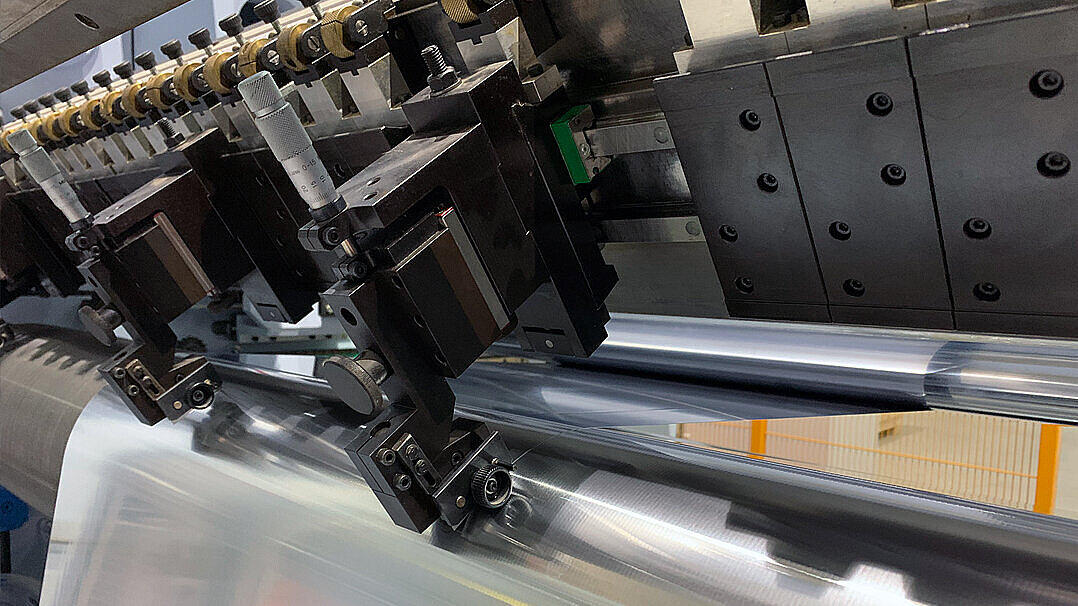

Slitting machines type LightSlit serve for slitting of both, soft annealed and full-hard aluminium foils, such as for example battery foils in strip thicknesses from 6 - 50 µm with maximum precision from a strip width of 25 mm up to a roll diameter of 800 mm.

Radially and axially positionable razor blades in the slitting section

Linearly retractable contact rollers

Shortest material ways

Battery Foil Pack

Achenbach OPTIFOIL LightSlit®

Rewinding diameters

Speeds

Coil weights

Foil thicknesses

A holistic approach.

They are tailored to the specific operation purpose.

For each new foil slitting machine or those to be modernized, a holistic approach to perfectly sychronize mechanics, hydraulics, automation, and drive technology in their complex interaction is applied.

- Radially and axially positionable razor blades in the slitting section

- Linearly retractable contact rollers

- Tracked and large-scaled input roller

- Material-conserving finished roll removal system

- Shortest material ways

- Free machine access

- Extended drive concept

- Battery Foil Pack

The Achenbach LightSlit® slits finished rolls for end products such as:

- Single-pass rolled battery foil for lithium-ion batteries

- Beverage container

- Chocolate wrapping foils

- Bottle neck foils

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.