Achenbach OPTIFOIL

HeavySlit®

ACHENBACH OPTIFOIL®

HeavySlit

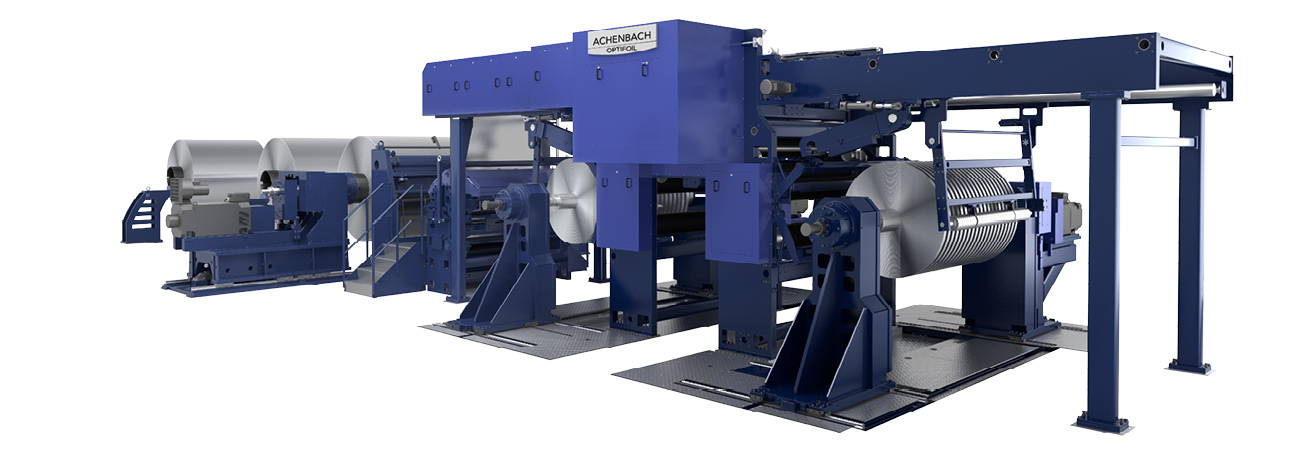

Slitting machines type HeavySlit serve for slitting stronger aluminium as well as copper and brass foils huge finish rolls in narrow strips of minimum 10 mm width.

Integrated oil applicator with individually adjustable oil application rollers

Adaptive rewinding and pressure system with four operation modes

Stable, highly precise slitting cassette with optional axial micro-adjustment

Patented single contact roller system at the rewinder

Quick changing device for winding shafts

Rewinding concept mechanically decoupled from the main machine

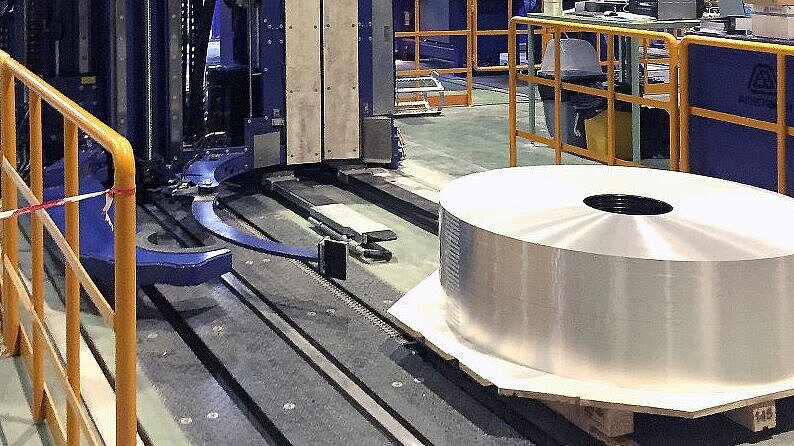

Achenbach OPTIFOIL HeavySlit®

Rewinding diameters

Speeds

Coil weights

Foil thicknesses

A holistic approach.

Designed either with pivoted or horizontally shiftable rewinding unit they are always tailored to the specific operation purpose.

For each new foil slitting machine or those to be modernized, a holistic approach to perfectly synchronize mechanics, hydraulics, automation, and drive technology in their complex interaction is applied.

HeavySlit generally comes in two different designs:

- with swivel winder

- with horizontally movable winder

Every Achenbach HeavySlit® features very short material transport paths and a highly precise slitting device, equipped with either shear-cut or rotary shear-cut technology. Material feeding and finished roll handling are highly customizable.

- Adaptive rewinding and pressure system with four operation modes

- Stable, highly precise slitting cassette with optional axial micro-adjustment

- Patented single contact roller system at the rewinder

- Integrated oil applicator with individually adjustable oil application rollers

- Rewinding concept mechanically decoupled from the main machine

- Automatic integration of following further processing and packaging systems

- Quick changing device for winding shafts

The Achenbach HeavySlit® produces finished rolls as the starting material for end products such as:

- Heat exchanger fins

- Tube stock

- Semi-rigid food containers

- Closure stock

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.