VIBRATION

MONITORING

OPTILINK Vibration Monitoring:

Early detection of irregularities to increase the efficiency of production

Every rotating machine has a unique vibration signature. If the vibration changes, this can be an indication of potential faults. Even small defects in components cause a change in the vibration characteristics of the component, which can be detected and evaluated with suitable evaluation algorithms. The OPTILINK Vibration Monitoring System (VMS) makes it possible to identify these changes in vibration that indicate potential faults.

Especially in the mechanics of the machine, e.g. in the gears or in large bearings, failures caused by wear during production can cause enormous damage to the machine. In addition, for components with a long delivery time, the repair cannot be carried out during the delivery time and there is a risk of a long, unplanned machine downtime. This is particularly unpleasant in phases with high machine utilization. Using vibration sensors, it is possible to detect many of the faults caused by wear at an early stage.

The targeted analysis of vibration data enables the prediction of various types of damage to mechanical components such as bearings or gears at an early stage as well as the detection and prevention of material damage caused by mill chatter or overloading of mechanical components. By defining monitoring tasks, key figures are extracted from the different vibration data and monitored.

Monitoring and measuring changes in vibration

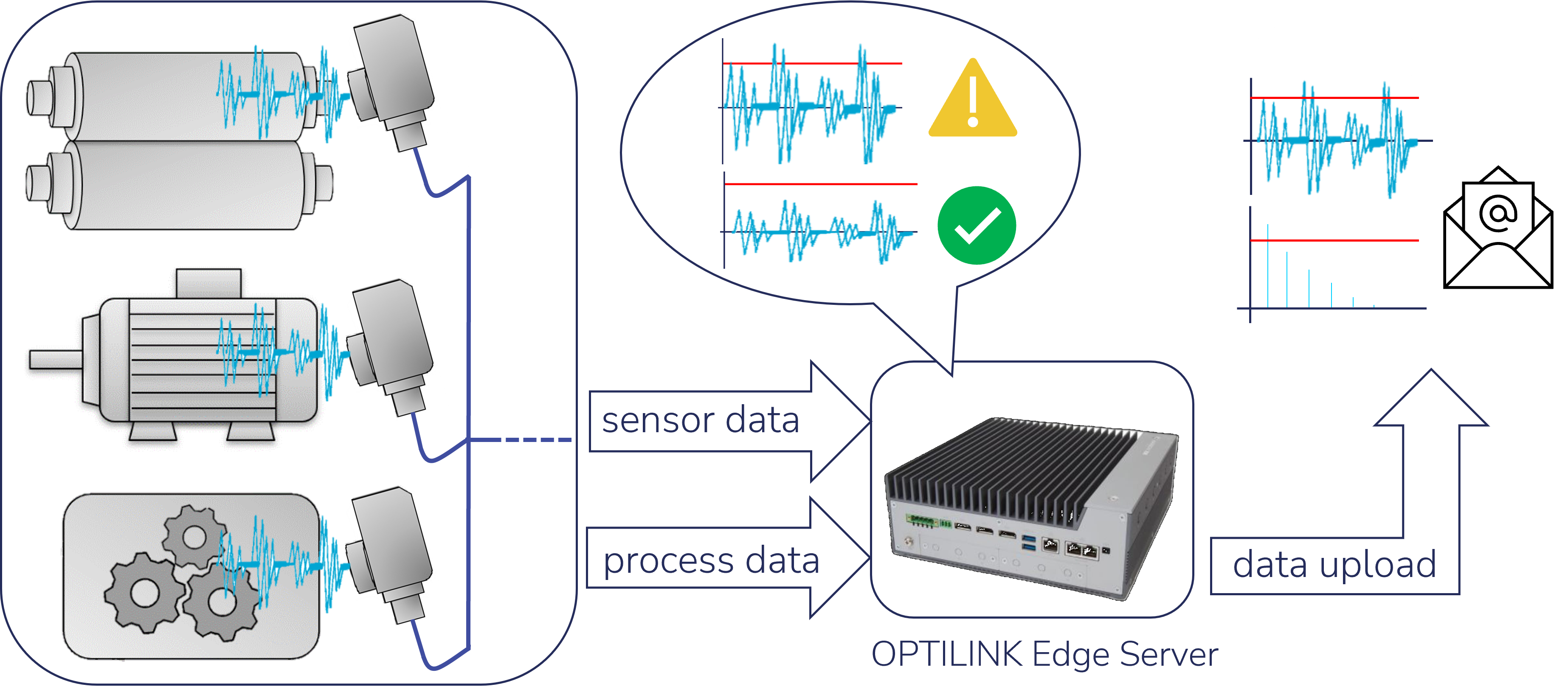

Using special sensor technology, it can record vibrations from roller sets (chatter), bearings, gears, or pumps with sampling rates of up to 51 kHz and evaluate them on site. The evaluation takes place on a so-called ‚edge gateway‘, which serves as an interface between the automation level and the cloud. With the help of different analysis algorithms, it can detect increased vibration amplitudes that differ from the normal state while still in the customer's machine network and react accordingly. Signs of bearing wear e.g. are shown by pittings in the races or in the rolling elements of the bearing. As soon as these pittings are overrun by the rolling elements the amplitude of the characteristic frequencies of the bearing increases. Also tooth wear in gears can cause a rise of amplitudes in the specific frequencies. Knowing these characteristic frequencies, a warning system is set up that monitors particularly important machine parts continuously and, in many cases, detects a fault so early that the necessary spare parts can be ordered and delivered and repairs can be carried out before the fault leads to machine failure.

Another useful application for vibration sensors in rolling mills is what is known as chatter monitoring. 'Chatter' is a material defect that can be caused by vibrations in the roll set during production. Using 'chatter monitoring', the module monitors the frequencies that are critical here and can generate a warning to the machine operator if the limit value is exceeded.

In contrast to other solutions, the OPTILINK-based 'vibration-based condition monitoring' module actively monitors the vibration characteristics. In addition to the vibration sensors, it uses other machine data such as status information, torque or rolling forces. Because the module automatically recognizes the change in the characteristic, regular checks of the measured values by the service employee are no longer necessary. Errors caused by the manual recording of measurement data, e.g. by choosing the wrong sensor location, are excluded. At the same time, the potentially critical vibration data is automatically transferred to the OPTILINK cloud. In this way, experts worldwide can easily access the vibration data and evaluate it.

Effective preventive maintenance

The 'vibration-based condition monitoring' module is a modern and efficient tool within the OPTILINK system that makes unplanned machine downtime avoidable and thus helps to maximize machine productivity. Taking action before failure occurs keeps equipment in peak operating condition longer. The early detection of irregularities gives the system operator up to several months to take remedial action, whereas in the past, simply observing processes, listening for unusual noises or scanning the machine for large temperature fluctuations often left only a few days or hours to intervene. Since all rotating parts wear out sooner or later, this technology can be used for effective preventive maintenance. Many incipient damages of turning mechanical parts can be detected using the techniques of vibration analysis. Due to the fact that the damages start small and increase over time, such a system enables the customer to plan a maintenance intervention and provide necessary spares in time.

The VMS is completely integrated into our OPTILINK system and uses its advantages such as 'smart alerting', 'widget views' and powerful reports. To evaluate error scenarios and anomalies, it is supplemented by an analysis dashboard with which the vibration data can be examined in the browser.

Benefits at a glance

- Permanent monitoring of condition and process of the machine in real time.

- Early detection of irregularities

- Proactive planning of maintenance measures

- Continuously ensuring and maximizing plant availability and machine performance

- Guaranteeing the safe operation of machinery

- Integrated into OPTILINK System

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.