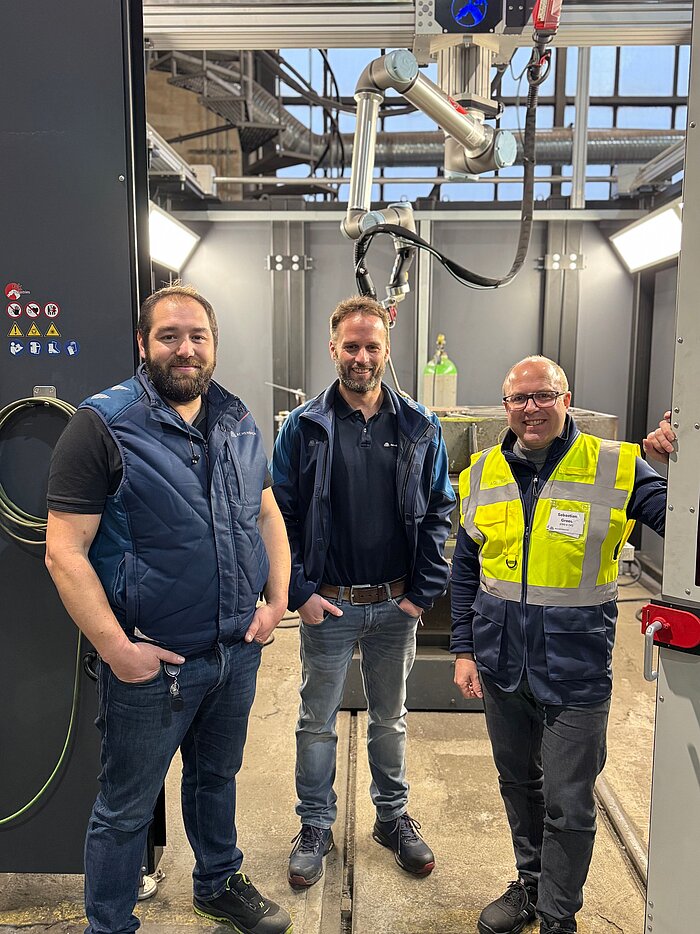

A successful start: On two recently modernized Achenbach OPTIMILL® Foil Rolling Mills at CBA | Companhia Brasileira de Alumínio, the first coil has been rolled successfully.

With the modernizations, CBA aims to ensure long-term performance and availability of its equipment. As a trusted partner — 60 years of collaboration and 16 delivered rolling mills — Achenbach was selected to upgrade the mills to state-of-the-art technology.

The scope included:

🔧 New roll setting system

💧 Achenbach UniSpray® Coolant Distribution System for high-precision oil application

📏 Achenbach UniFlat® Flatness Measuring Roll for optimized strip flatness

🧠 Achenbach OPTIROLL® i3 Package for rolling mill automation with efficient model-based control functions such as a high-precision strip thickness control (Mill Gauge) and a highly dynamic strip flatness control (Mill Flat).

These projects are a strong example of how legacy equipment (partly over 50 years old) can be transformed to meet today’s technical and operational requirements.

We thank CBA for their continued trust and look forward to further milestones together! A big thank you also goes to our team on site for their efforts.

Technology upgrades secure long-term mill performance at CBA

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.