Constellium has commissioned Achenbach to supply a new coiler for the combined hot-cold tandem mill – the core of the customer’s aluminium strip production in Singen.

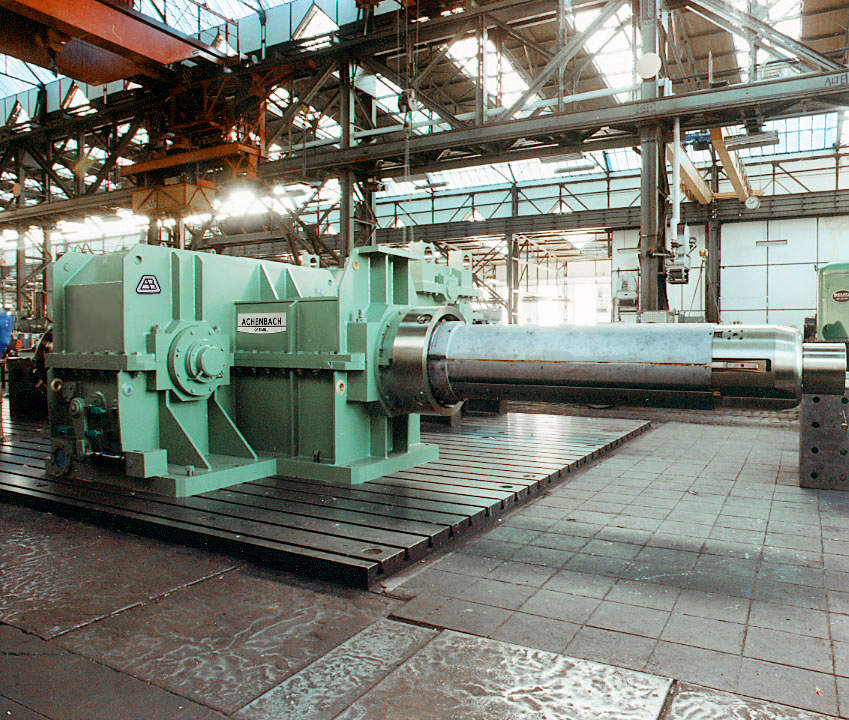

The new coiler replaces a roughly 50-year-old Achenbach unit that originally belonged to a cold rolling mill, which was relocated to Singen many years ago.

Achenbach prevailed against strong competition, as the customer values both the “Made in Germany” quality of supply and Achenbach’s recognized technical expertise. The Constellium project team was presented with several thoroughly engineered solution concepts, along with a detailed implementation plan tailored to a tightly defined schedule.

A key part of the delivery is the newly designed coiler gearbox, engineered for future rolling requirements and equipped with a gearbox-specific condition monitoring system. This advanced system continuously monitors operating parameters and, with state-of-the-art sensor technology, ensures operation within defined limits – securing reliable performance for decades to come. ⚙️📊

We are looking forward to this project and to continuing our good collaboration with Constellium.