Achenbach OPTIMILL®

Strip rolling mill

Achenbach Optimill®

Strip Rolling Mills

Achenbach Strip Rolling Mills reliably produce best strip qualities even at maximum rolling speeds, maximum rolling widths, and highest coil weights.

High Efficiency Fume Hoods

Achenbach OPTIROLL® i3 System for integrated, digital, modular designed automation

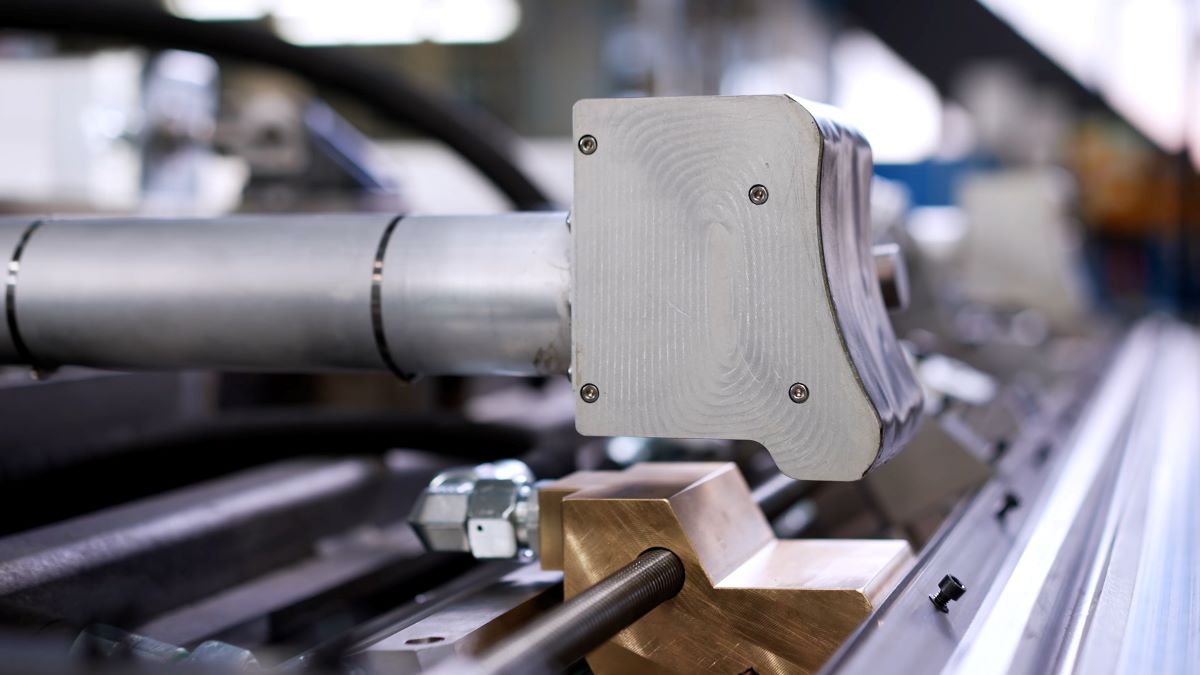

Achenbach UniHeat Curved Hot Edge System for precise strip edge heating

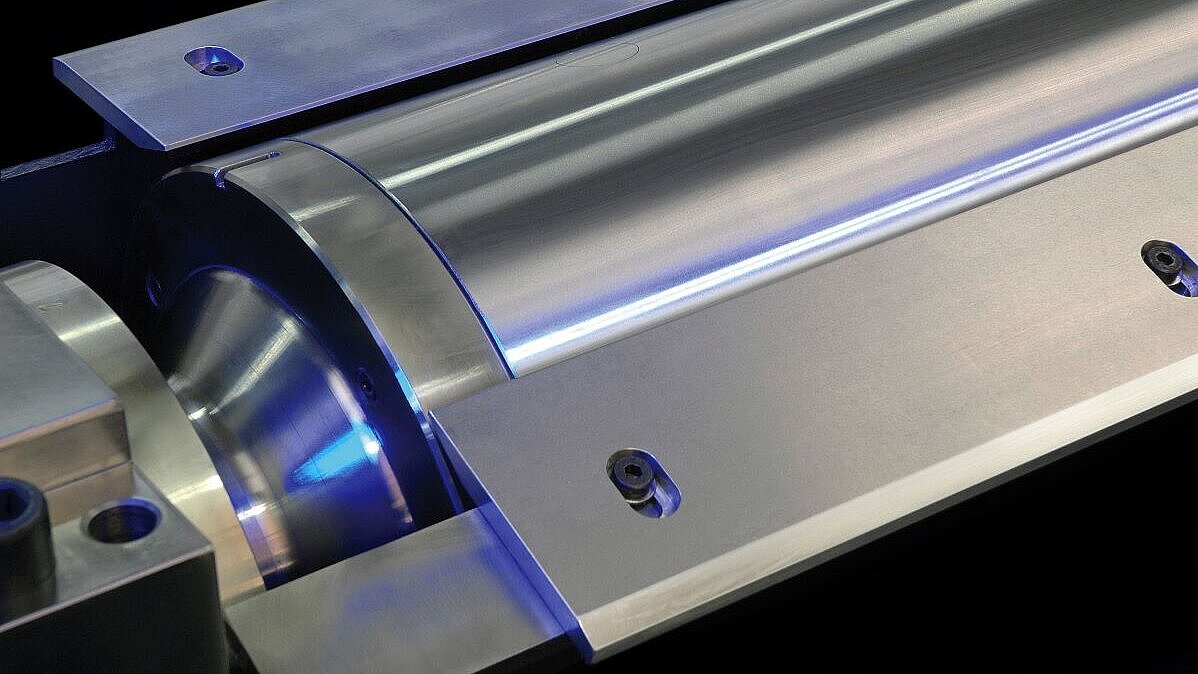

Achenbach UniFlat® Flatness Measuring Roll for high precise flatness measuring

Achenbach OPTIMILL® Aluminium Strip Rolling Mills

Strip widths

Rolling speeds

Final rolled thicknesses

Coil weights

A holistic approach.

Designed either as 6-high or 4-high rolling mills they are always tailored to the specific operation purpose. Special applications, e.g. as bright rolling mills, require the 2-high rolling mill design.

For each new strip rolling mill or those to be modernized, a holistic approach to perfectly synchronize mechanics, hydraulics, automation, and drive technology in their complex interaction is applied.

The outstanding performance is achieved by automation with Achenbach OPTIROLL®.

The Achenbach OPTIPURE® Media Systems for economically and ecologically efficient exhaust air purification, rolling oil filtration, and rolling oil rectification complement the machinery for an optimum rolling process.

Achenbach offers the following types of strip rolling mills:

- Six-high rolling mills

- Four-high rolling mills

- Two-high bright rolling mills

- Achenbach OPTIROLL® i3 System for integrated, digital, modular designed automation

- Achenbach UniHeat® Advanced Hot Edge System for precise strip edge heating

- Achenbach UniFlat® Flatness Measuring Roll for high precise flatness measuring

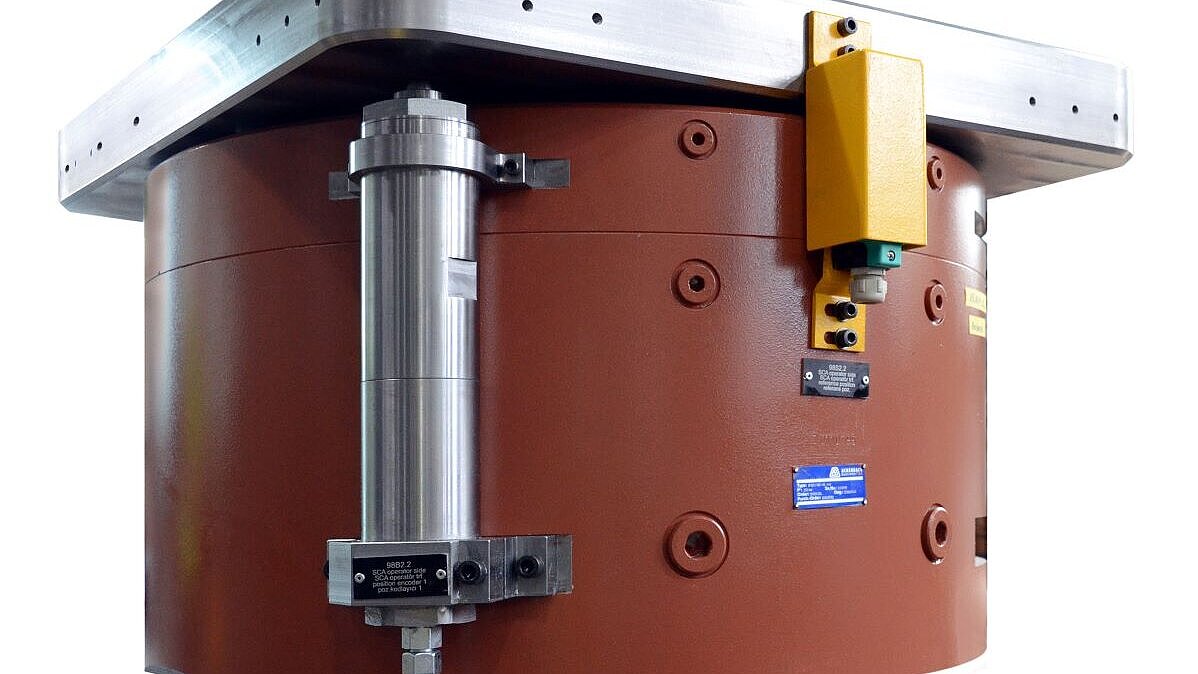

- Sensor-initiated roll gap quick opening system by setting cylinders located at the bottom of the mill stand

- Achenbach DVC Back-Up Roll System with dynamically variable adaption of the crown

- Material-flow optimized coiler system with minimized auxiliary times

- High Efficiency Fume Hoods

- Coil preparation station

Achenbach Strip Rolling Mills produce aluminium strips as the starting material for all aluminium thin strip rolling processes respectively for end products such as:

- Foil stock strip

- Aerospace- and aircraft strip

- ABS Automotive body stock

- Can end & can body stock

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.