Achenbach OPTIFOIL

JumboSlit®

ACHENBACH OPTIFOIL®

JumboSlit

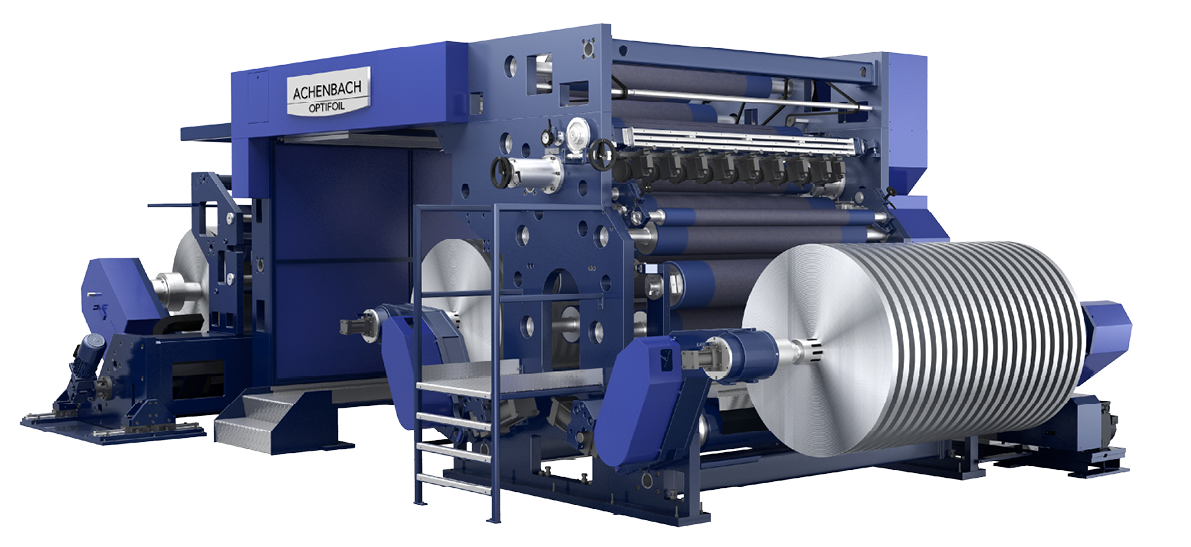

Slitting machines type JumboSlit serve for slitting thin aluminium, as well as copper and brass foils, or compound materials to small strips of minimum 10 mm width.

Integration of customer-specific measuring systems: surface inspection, inspection of paint defects, etc.

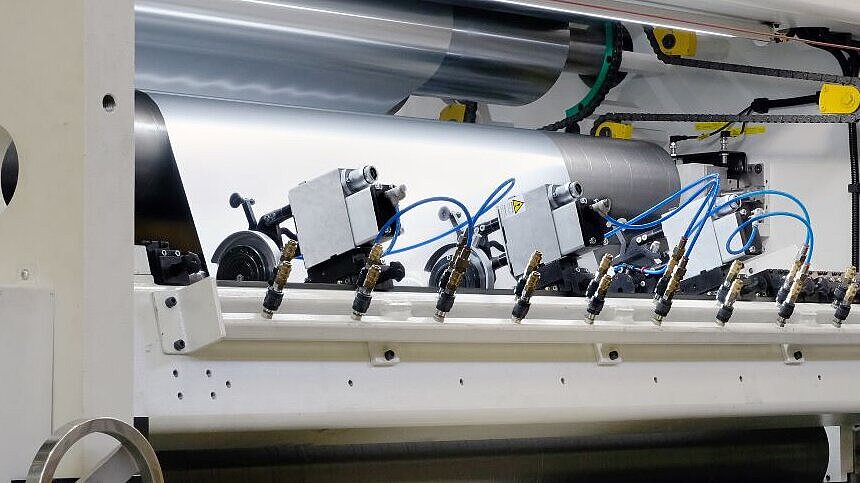

Achenbach UniLub Oil Application System for single or double-sided material lubrication

Rewinding concept with stable, pivoted winding arms in combination with hydropneumatics contact roller system

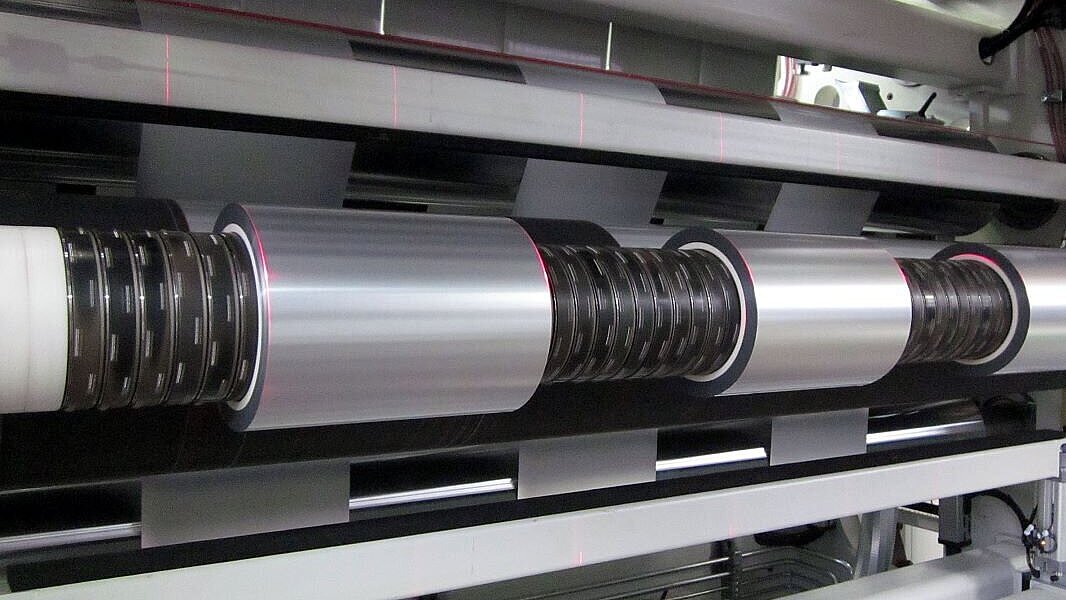

Integrated stable slitting section with top knife shaft or single knife holder

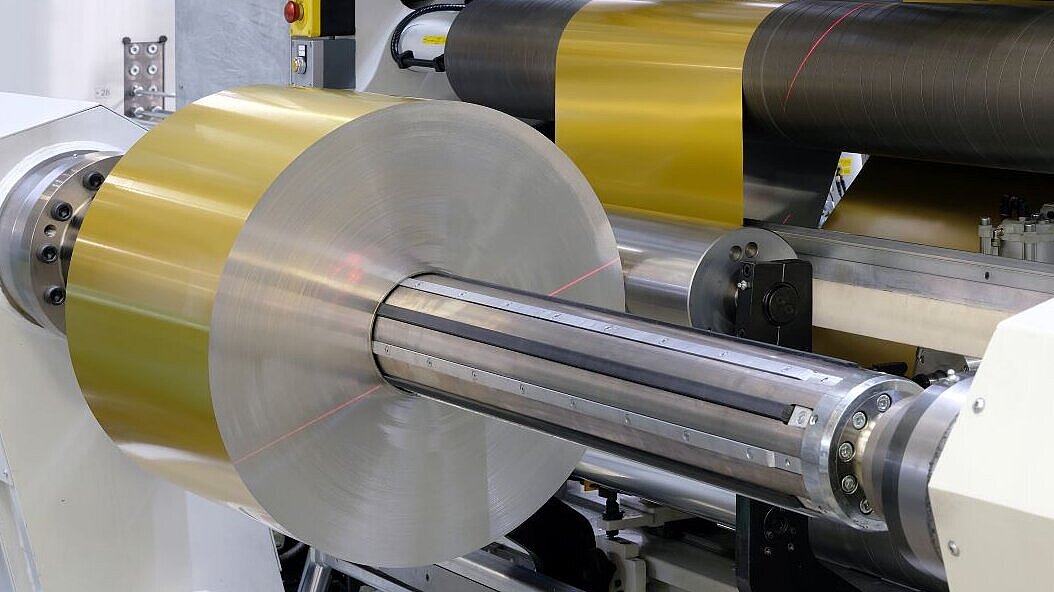

Unwinder with lifting function

Achenbach OPTIFOIL JumboSlit®

Rewinding diameters

Speeds

Coil weights

Foil thicknesses

A holistic approach.

They are tailored to the specific operation purpose.

For each new foil slitting machine or those to be modernized, a holistic approach to perfectly sychronize mechanics, hydraulics, automation, and drive technology in their complex interaction is applied.

OPTIFOIL JumboSlit® works with two oppositely arranged winding units and comes in three different designs:

- Swivel winder

- Single winding station

- High-speed turret winder

Every JumboSlit features very short material transport paths and a highly precise slitting device, equipped with shear-cut, rotary shear-cut, or razor-blade technology. Material feeding and finished roll handling are highly customizable.

- Functional operation

- Achenbach UniLub Oil Application System for single or double-sided material lubrication

- Rewinding concept with stable, pivoted winding arms in combination with hydropneumatics contact roller system

- Integration of customer-specific measuring systems: surface inspection, inspection of paint defects, etc.

- Integrated stable slitting section with top knife shaft or single knife holder

- Guide frame

- Unwinder with lifting function

The Achenbach JumboSlit® slits large rolls for end products such as:

- Coffee & tea capsules

- Converted foil

- Plastic foil

- Aseptic foil

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.