Achenbach UniFlat®

Low Inertia Flatness Measuring Roll

Achenbach

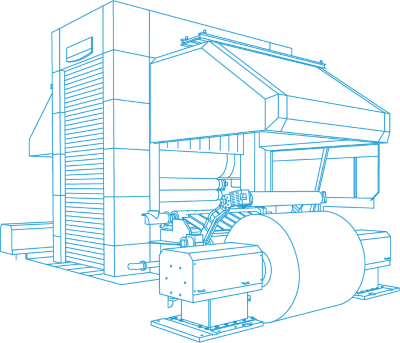

UniFlat® Low Inertia Flatness Measuring Roll

Essential technology component for permanent measurement of offline flatness and continuous monitoring of production qualities.

A holistic approach.

The Achenbach OPTIMILL® Low Inertia Flatness Measuring Roll is characterized by its very low weight, which makes it possible to integrate the drive

into the bearing housing. This innovation, together with the high-resolution electronics and sensors, results in a particularly high measuring sensitivity.

As no external drive components are required, the low inertia roll can be easily integrated into existing machines as a stand-alone solution for flatness measurement of not only non-ferrous metals but also plastic foils and paper.

- Recommended where finest flatness differences are to be measured by using a tactile measuring system

- Complete and continuous measuring of the final flatness in foil separators and strip processing lines

- Cost-effective alternative towards a separate inspector machine

- Complete substitution of an existing deflection roll and thus simple retrofitting of existing machines

At a glance

Thermal and mechanical effects during both, rolling and following production process can cause metallurgical modification with negative effects to the strip flatness. Such flatness defects can be recognized at an early stage and can even often be avoided by a continuous flatness measuring.

The individually adjusted and installed sensors guarantee an optimum measurement accuracy regarding the respective product range thanks to their extremely high sensitivity. Due to this high sensitivity, the measuring roll is also ideal for measuring plastic films produced in blown film and cast film lines.

No additional hardware, such as control systems, is required for measuring and evaluating flatness. Measurement and parameterization are performed on a standard PC.

Due to its modular design the Achenbach UniFlat® Low Inertia Flatness Measuring Roll can be used as an equivalent replacement for a separate deflection roll and is thus upgradable at many existing machines. Thus it is often a cost-effective alternative to a separate inspector machine.

Finally, the encapsulated electronic construction ensures both, maximum operational safety und highest maintenance friendliness with the advantage of a high flatness measuring roll availability guaranteed during operation.

- Very light and simultaneously robust design of the roll body as hollow cylinder

- Integrated drive in the bearing houses

- Maximum operational safety and high availability

- Roll surface also possible with CFP coating

- Up to 96 piezoelectric sensors with extremely high signal resolution

- Optimum measurement accuracy guaranteed

- Wear-free due to contactless measuring data and energy transfer

- High maintenance friendliness by fast and convenient removal and installation

- Since the measurement is performed on a PC, no additional hardware is required

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.