SHOPFLOOR

DATA ACQUISITION

OPTILINK Shopfloor Data Acquisition:

Collecting real-time data from machines and processes to provide appropriate advice for process optimization

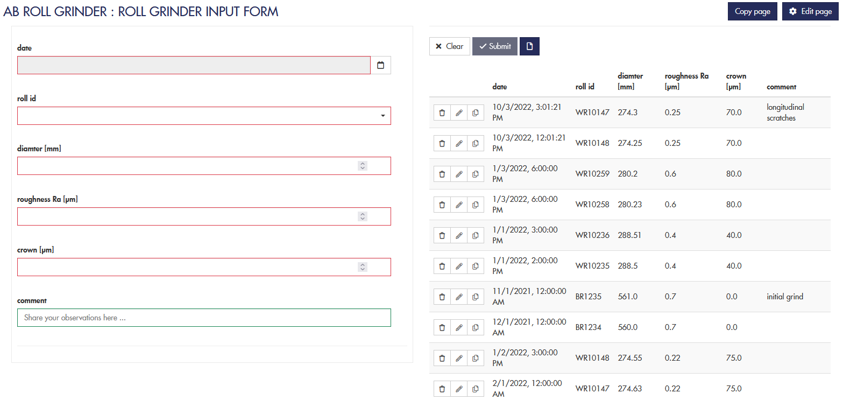

With Achenbach OPTILINK, production data is automatically recorded and digitized. Converging OT and IT enables you to achieve the full process visibility needed for informed decision-making. By processing and analysing data, it is possible to gain insights and understanding of the customers processes and their products to provide appropriate advice and expertise. This is an important information basis for Achenbach's UniSkill process consulting. Extensive data collection with OPTILINK can be established across all rolling mills to enable detailed pass schedule analysis and root cause investigations. OPTILINK can also provide data from preliminary passes from other machines. The integration of data from the grinding shop and the laboratory, such as rolling oil information and work roll specifications, further enhances the analysis capabilities. This data-driven approach for process optimization is the key to achieving the desired product quality specifications.

The expansion of the human-machine interface goes far beyond a conventional HMI, e.g., via mobile devices and channels such as WhatsApp. In addition to production data, laboratory data and data from the grinding shop can also be taken into account.

Benefits at a glance

- Better transparency regarding the current status of production and assistance in identifying bottlenecks or problems

- Automated data collection and processing increases efficiency in the production environment

- Early error detection and quality control

- Better communication and collaboration at the shop floor level

- Enabling data-driven decisions that optimize the entire production

“In collaboration with Achenbach LCS team by using OPTILINK, we successfully tackled flatness quality challenges on specific materials. OPTILINK played a crucial role in computing defined KPIs and monitoring the impact of process adjustments, resulting in significant improvements to our targeted product groups. The system is a comprehensive toolkit also promising optimization opportunities for our wide range product portfolio. It also allows us to have a quick and useful overview of the mill parameters, both in real-time and retrospectively.”

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.