ROLL

MANAGEMENT

OPTILINK Roll Management:

Tracking roll changes and grinding histories precisely and address individual roll failures proactively

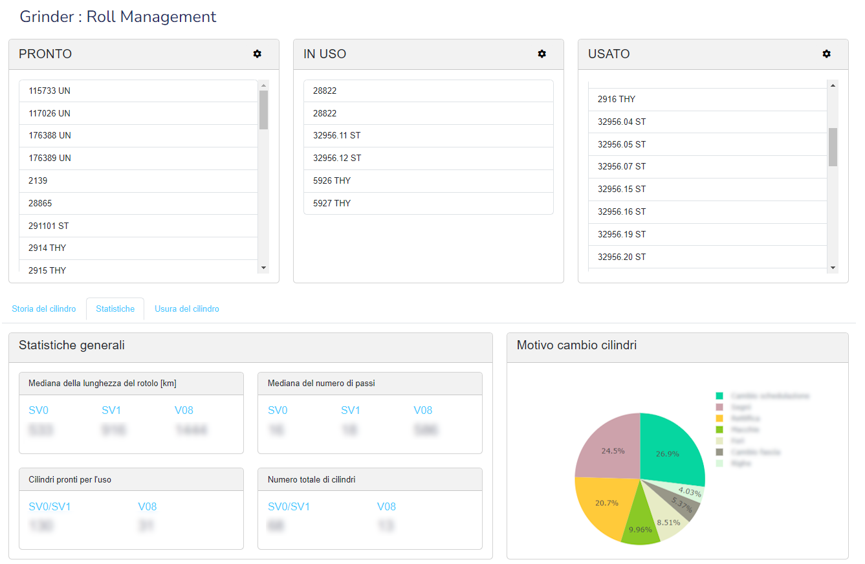

The quality and condition of the work rolls is crucial for a functioning foil rolling process. In many cases, the work rolls and their condition are only recorded to a limited extend by IT. Connecting the roll grinding shop with OPTILINK, data such as roll roughness, or the roll crown are recorded via input masks on the roll grinding machines and are also available for process analysis. A second input mask is available for roll changing at the rolling mills. Input fields such as the reason for change and free comment fields allow to record production information in a structured manner.

The recorded data can then be used to provide you with an overview of the condition of the rolls and to generate additional information such as the number of rolls ready for installation for a specific process step.

Benefits at a glance

- Overview over roll condition

- better coordination of rolling and grinding processes

- Proactively identify and correct individual roll failures

“We have implemented digitalized roll management with Achenbach OPTILINK®. It provides our production teams at the grinding workshop and rolling mills a quick access to the same information.

This system enables us to precisely track roll changes and grinding histories.

The rolls dashboard further empowers us to pinpoint and address individual roll failures proactively.”

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.