OPTIMIZING

COIL CHANGING DURATION

OPTILINK Optimizing Coil Changing Duration:

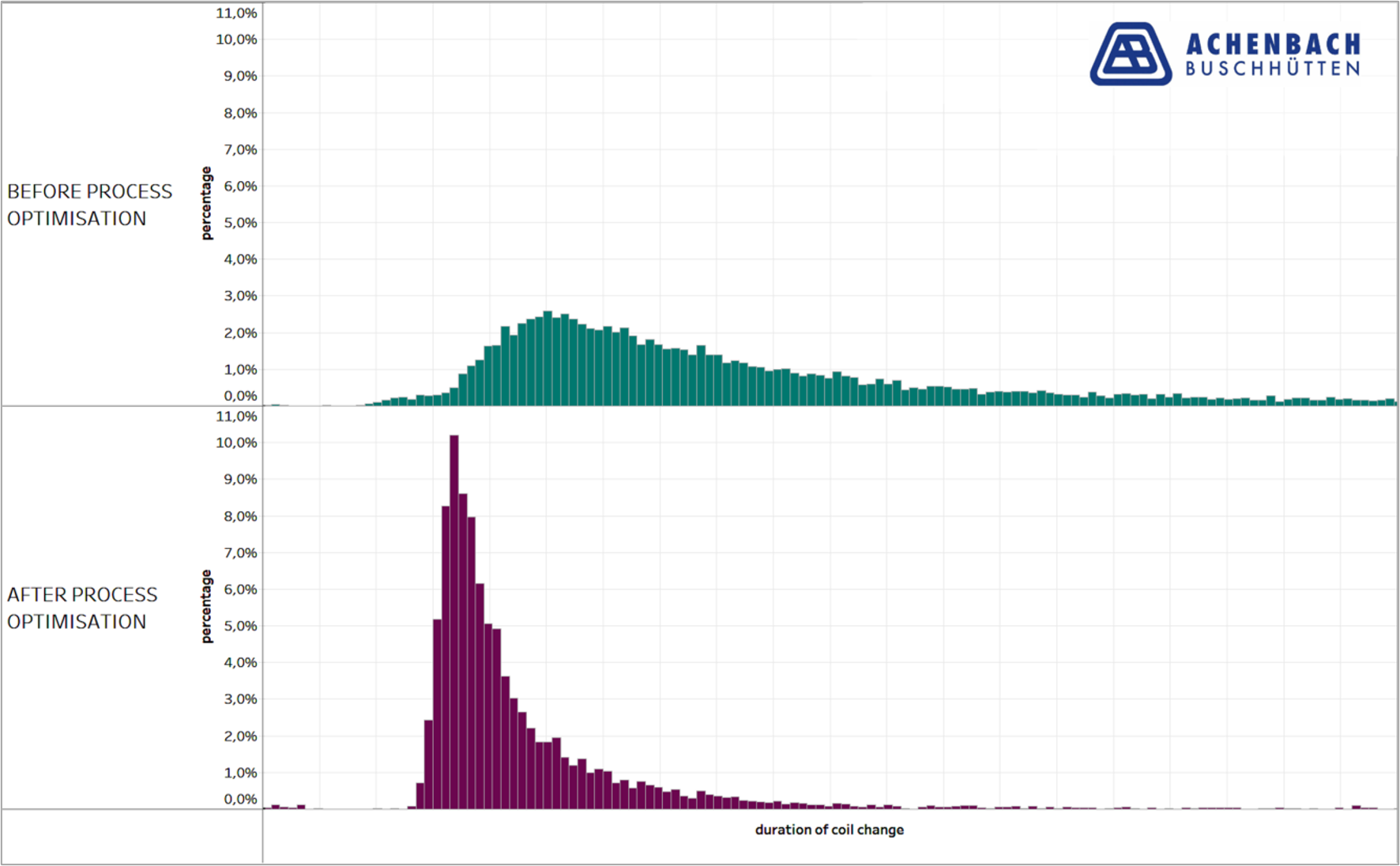

Measuring and optimizing non-productive times as a basis for improvements

OPTILINK in combination with UniSkill, the process consulting service of Achenbach Life Cycle Support, can be used to optimize non-productive time. Supported by the data in OPTILINK, the process experts can develop measures tailored to your needs, which improve coil change times through better logistics, work preparation and personnel training.

OPTILINK can also be used to document the success of the measures. The dashboards for measuring non-productive times are available to you as standard and can be used as a starting point for improvements.

Benefits at a glance

- Overview over non-productive time

- Targeted process optimization based on broad data base

- Higher production efficiency

“We wanted to track the coil change time in the mill following precisely our companies own standard definition of TAT (turnaround times). With the broad data base of OPTILINK and in cooperation with the Achenbach team this task was easy to solve. With the help of the new dashboards, we have gained deeper insights into the TAT and in which areas there is potential for optimization.”

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.