LUBRICATION OIL

SUPERVISION

OPTILINK Lubrication Oil Supervision:

Preventive Maintenance

Don’t let hidden lubrication issues lead to costly bearing or gear damage. Unlock proactive maintenance with OPTILINK’s Lubrication Oil Supervision system. The intelligent oil condition sensor system empowers you to continuously monitor the vital physical properties of your lubrication oil.

The sensor measures key physical oil parameters, including temperature, oxidation level, additive consumption, acidity, alkalinity, base content, and viscosity changes. It also detects contaminants such as soot, glycol, and metallic particles, as well as conditions like scorched oil. This comprehensive analysis enables the detection of issues like abrasive wear, component wear, coolant leaks, rolling oil leakage into lubrication oil, and thermal degradation.

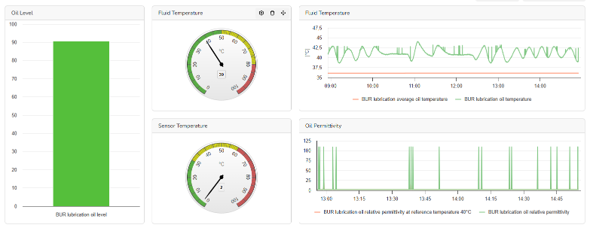

All measured signals are clearly displayed on your intuitive OPTILINK dashboard. Your maintenance team can easily set customized warning limits and receive instant alerts when values approach or exceed critical limits, enabling proactive intervention.

Benefits at a glance

- Delivers enhanced insights into the machine's overall health status

- Prevents costly damage and enables proactive maintenance

- Provides continuous monitoring and alerts

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.