ENERGY

MONITORING

OPTILINK Energy Management Tool (EMT):

Availability of live energy consumption and CO2 emissions at product level

Climate change and the shift to CO2 neutral production are major issues for companies. OPTILINK offers an advanced solution for monitoring and optimizing energy consumption in production. The new system allows the product-related carbon footprint to be tracked along the entire value chain and the energy efficiency of production processes to be optimized by means of specific data insights and monitoring functions. Developed specifically for operators of rolling mills and foil slitting machines, companies from other industries can also benefit from the system's optimal connectivity and analysis capabilities to keep an eye on energy consumption and costs. The OPTILINK EMT is listed as eligible energy management software according to ISO 50001, which is why German customers in particular benefit from a government grant.

Availability of live energy consumption and CO2 emissions at product level

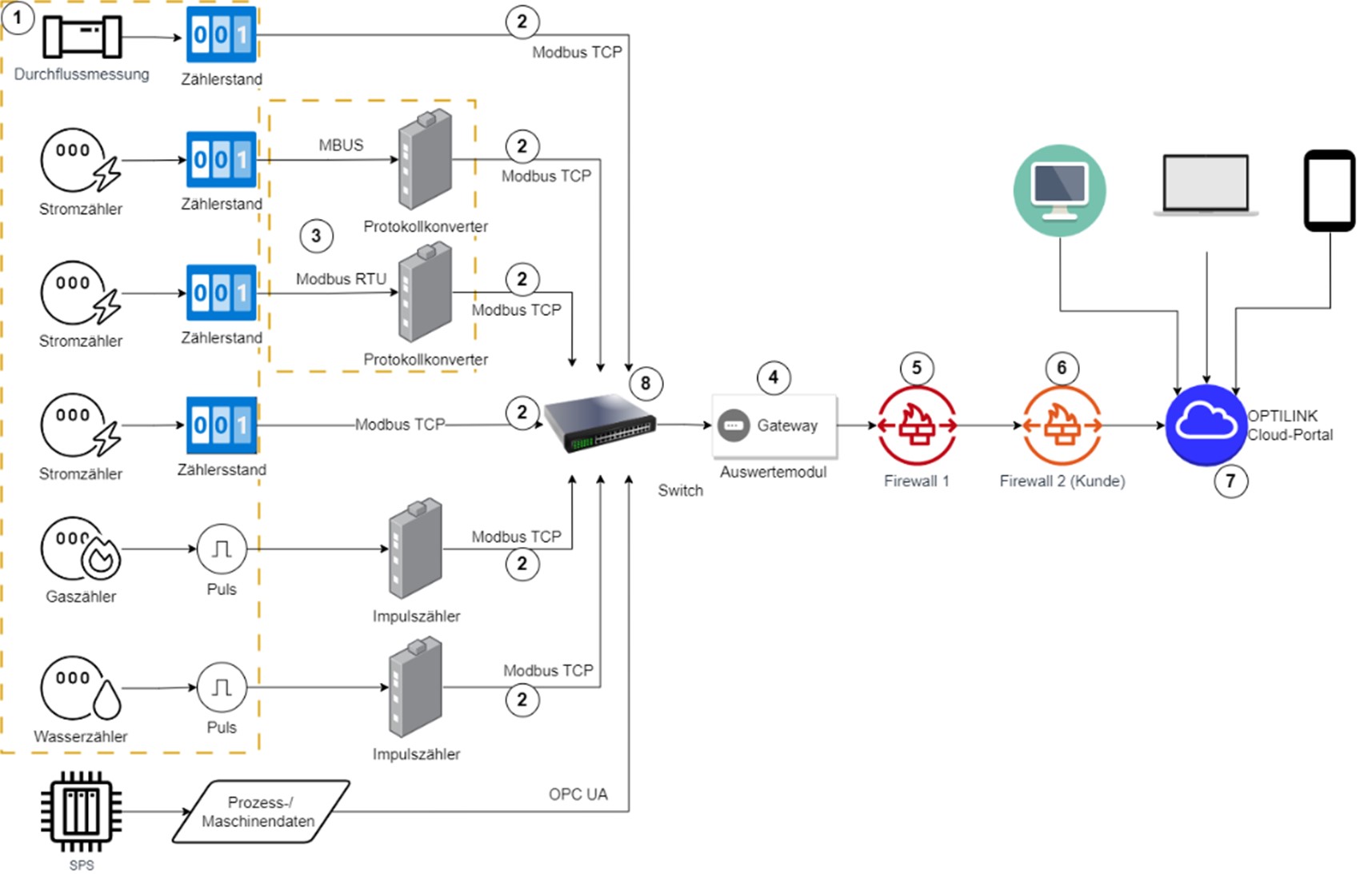

Based on reporting and analysis functions, the OPTILINK Energy Management Tool provides all relevant production energy data collected and analysed in real time using IoT technology. Doing so, the system supports typical interfaces and communication protocols for energy measurement. Both automatic, protocol-supported reading of energy meters, manual data entry, and data upload are possible. OPTILINK EMT offers a variety of energy focused dashboards such as Sankey-diagrams, map views and heat maps that quickly draw attention to corresponding hotspots with energy efficiency improvement potential. In addition to energy consumption n KWh, load profile, energy costs and CO2 emissions can also be displayed. The range of functions is particularly tailored to the requirements of the rolling mill but can also be used independently of the industry.

By interacting with detailed production data from the OPTILINK system, company-specific energy indicators can be monitored at various aggregation levels from the entire plant to the individual coil, and precise, unit-related energy consumption such as kWh per coil, kWh per alloy-ton or CO2 per m³ of material can be reported. The system can thus allocate energy costs and the CO2 backpack specifically on a product basis. This ensures precise efficiency computations even if the production mix changes continuously as in the case with most of our customers.

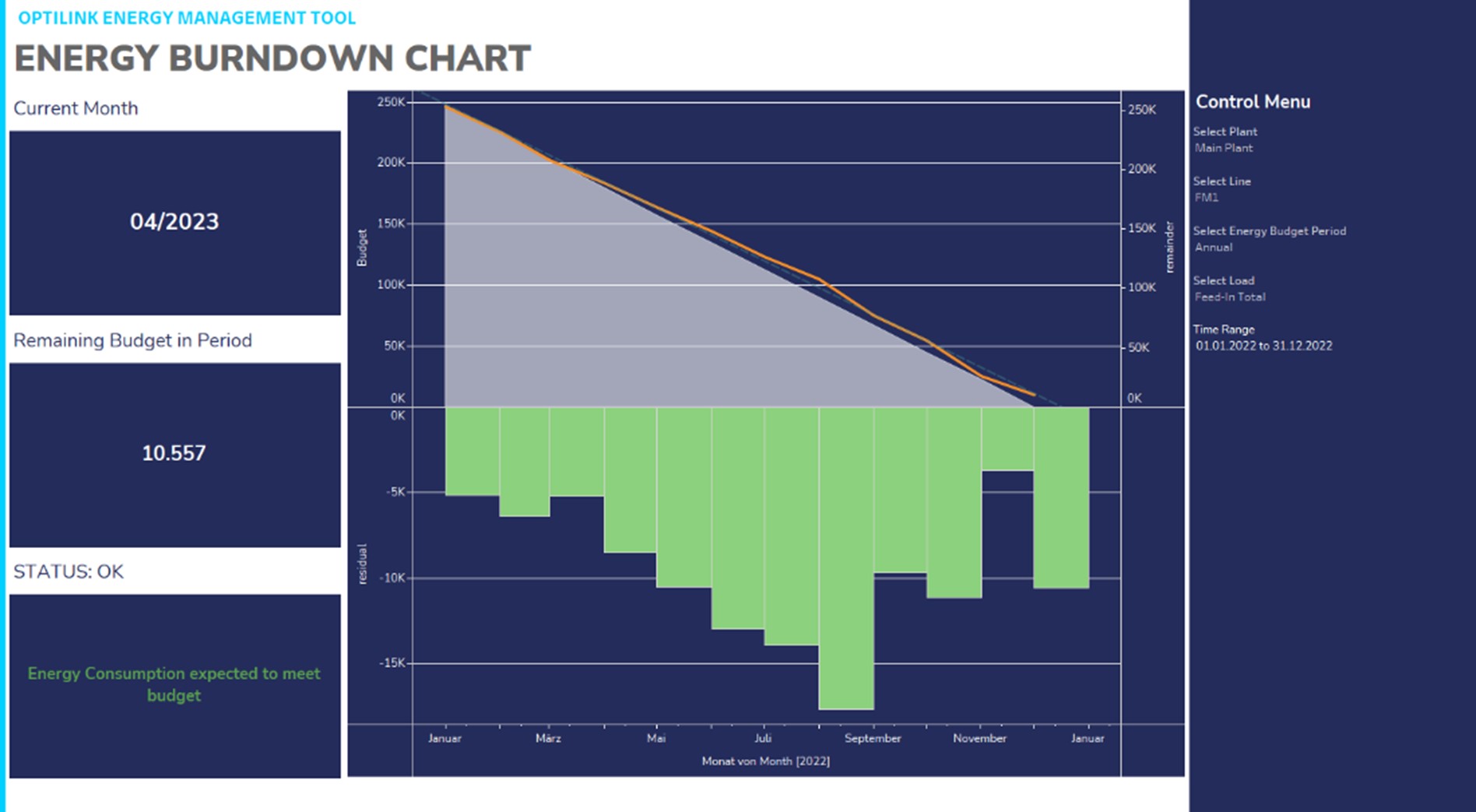

Based on a special dashboard (Energy Burndown Chart), compliance with targets such as period-based energy consumption contingencies or explicit energy targets can be monitored. If the configured consumption exceeds limits and target ranges, this is displayed accordingly and indicated via an active event and alarm interface (visualization, e-mail and Whatsapp). Based on AI, certain anomalies such as unexpected power peaks can be detected.

ISO-compliant energy reporting and Plan-Do-Check-Act-based tracking of energy activities

As the OPTILINK EMT is an advanced solution for monitoring and optimizing energy consumption and designed to assist in achieving sustainability goals, it is listed as a complete energy management software according to ISO 50001, an international standardization for energy management systems.

Energy activities are considered a continuous improvement process within the PDCA (Plan-Do-Check-Act) cycle by tracking strategic and operational energy goals, managing action plans and investments, and generating time- and event-driven energy reports for management reviews, internal audits, and certifications. Thus, all data collection, analysis, and management processes are integrated into one system.

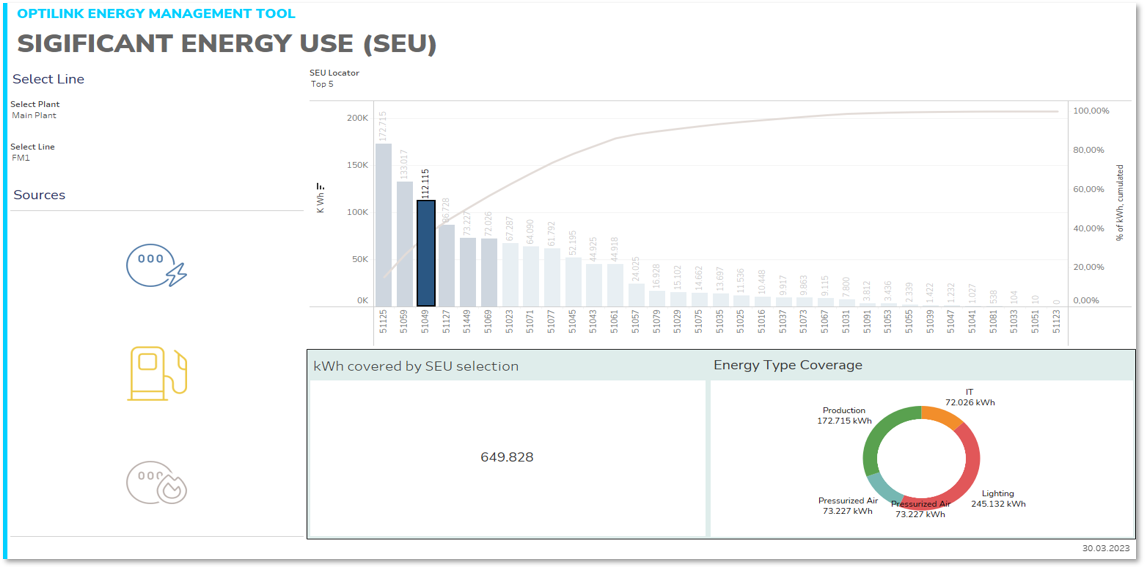

An elementary component of the PDCA cycle according to ISO 50001 is the analysis of the significant energy users (SEUs), i.e. consumers (consumer groups) with a significant share of the total energy consumption or with a large potential for improvement. With OPTILINK, these drivers can be precisely identified according to their company-specific significance.

German customers benefit from BAFA subsidy

Since the OPTILINK system is listed as eligible energy management software, German customers benefit from a government grant if they decide to introduce or expand their own energy management with OPTILINK. The OPTILINK EMT can be used in new plants as well as retrofitted. Incidentally, companies from all industries can benefit from the system's optimal connectivity and analysis capabilities to monitor energy consumption and costs.

Benefits at a glance

- Monitoring and optimizing the energy consumption of almost the entire machine park

- Tracking and reporting upstream and downstream emissions

- Gaining in-depth insights into energy consumption and CO2 emission values per rolled coil

- Increasing energy and resource efficiency significantly

- Integrated into OPTILINK System

- Listed as an overall energy management software according to ISO 50001

“Before starting with OPTILINK EMT we already had installed infrastructure for energy monitoring, but it was a tedious task to collect the relevant data from the various collection points. With OPTILINK EMT, energy consumption data now integrates smoothly with our production metrics. This consolidation expands our ability to identify the energy consumption of specific products and evaluate the impact of measures aimed at increasing the energy efficiency of our plant.”

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.