CROSS MACHINE

ANALYSIS

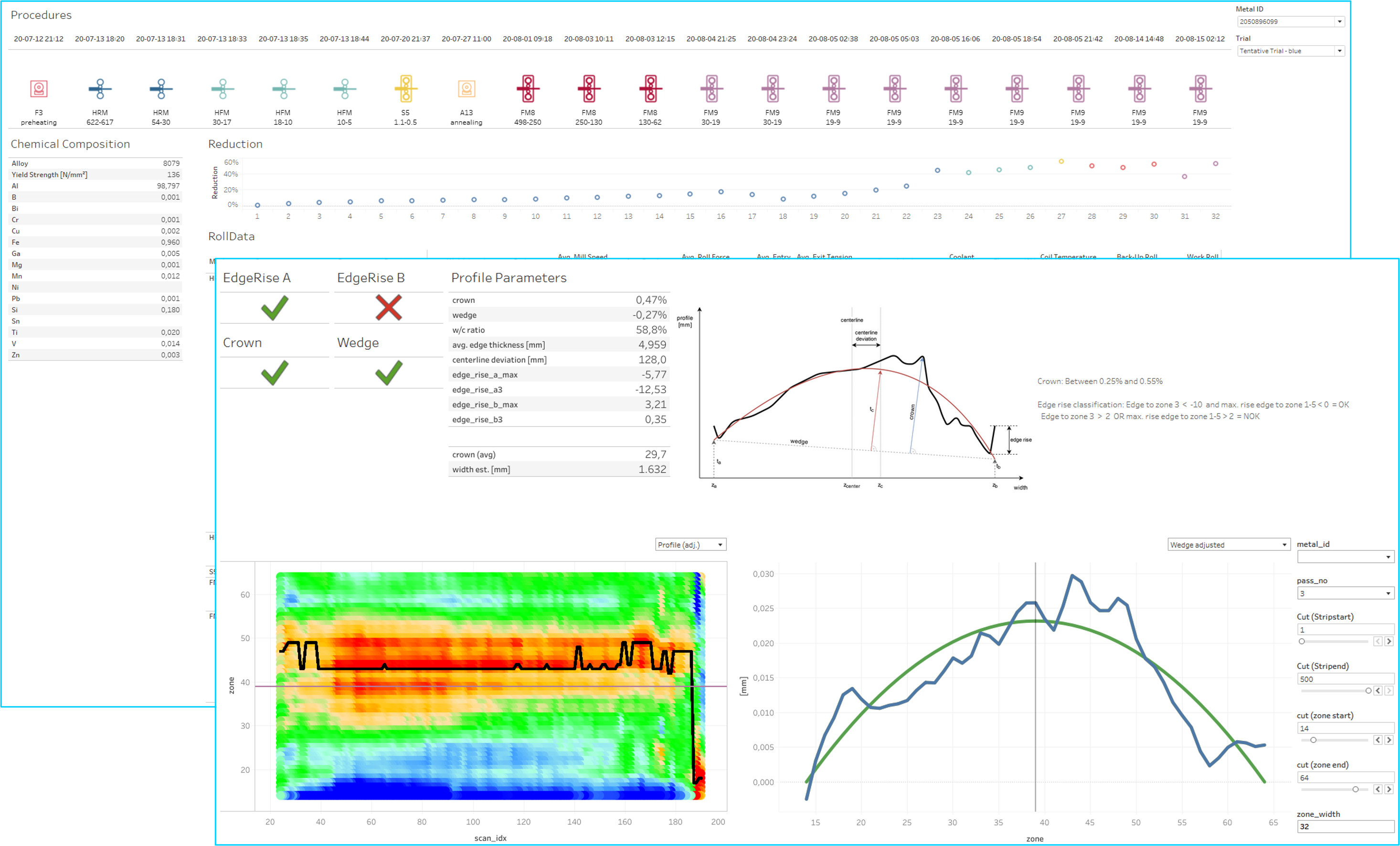

OPTILINK Cross Machine Analysis:

Comparing data across multiple machines to find patterns, issues or improvements

Achenbach OPTILINK® unleashes its full potential if multiple machines are connected. A common and high-quality database allows cross-machine analyses and even cross-plant analyses to be performed easily and in a time-saving manner. Analyzing the data from all machines involved in the production process Achenbach´s experts together with your team are able to correlate problems in the later production stages to issues in earlier stages. For example, a problem regarding the flatness of foil can be traced back to inadequate settings in the hot mill. Achenbach OPTILINK® enables to monitor and analyze a product from the caster to foil separation and slitting.

Benefits at a glance

- Comprehensive overview of the entire production chain

- Root cause analysis across the entire process chain

- Easier identification and elimination of sources of quality defects

- Optimal basis for energy consumption issues

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.